Marble and granite floors

Marble is a metamorphic rock. In the process of marble formation, small crystals of stone melt into larger crystals when exposed to different temperatures and pressure conditions. This is where marble gets its layered or banded texture.

Marble is usually used in various decorative solutions. This with the physical properties of marble. Marble surfaces have more humidity fluctuations and are not subject to temperature extremes.

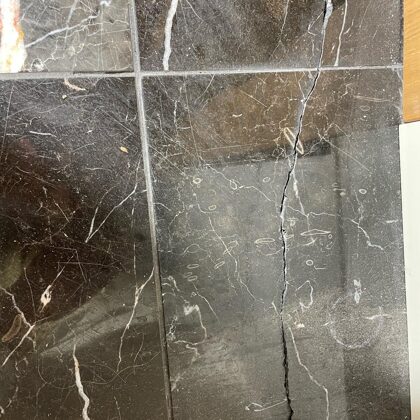

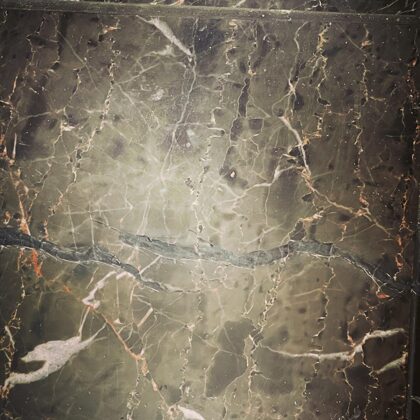

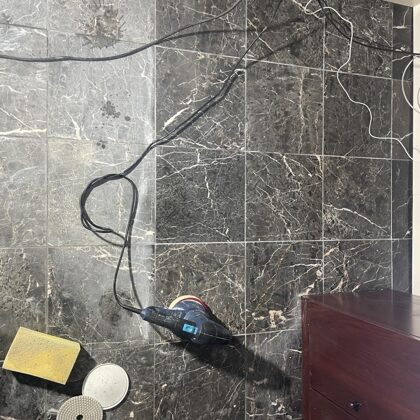

It is possible to restore marble and stone flooring with diamond grinding wheels, as well as kitchen surfaces. With dry sanding, wet polishing. Apply a protective layer. Repair:

- cracks;

- seam areas

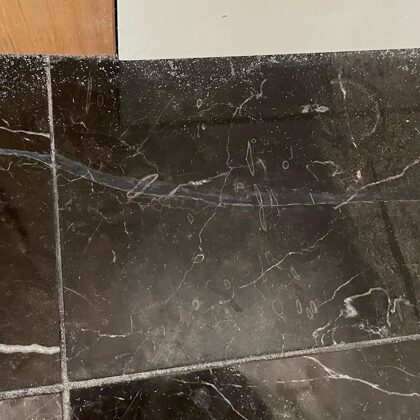

- dirt

- irregularities;

- tile deposits.